Description

An unquestionable advantage of FENIX BLUE injectors is speed and short opening stable times. These injectors are also characterised by high stability of gas flow, and very presise fuel dosage in dynamic conditions. This is especially important for direct injection engines, due to their dynamic character. In order to provide a high quality injector, KME being a producer of complete autogas systems, implemented necessary parameter control system, and also secured the right selection of components.

The product contains seals made of rubber-based mixtures (FKM) and modern fluoropolymer sliding coatings (non-stick and anti-freeze) that make the injector extremelly resistant to fuel pollution and low temperatures. The injector is equipped with a standard Superseal 2-pin connector.

When mounting FENIX BLUE injectors, you can use either manifolds, or dedicated elbows, and knees. It is a very helpful tool for an installer, as they facillitate mounting the injector, even in difficult to access area.

The injector nozzles selection

|

Ø [mm] |

1,0 [bar] |

1,25 [bar] |

1,5 [bar] |

||||

|

17÷23 HP | KM |

19÷25 HP | KM |

21÷28 HP | KM |

||||

|

24÷28 HP | KM |

27÷32 HP | KM |

31÷36 HP | KM |

||||

|

31÷35 HP | KM |

35÷40 HP | KM |

39÷45 HP | KM |

||||

|

37÷40 HP | KM |

43÷46 HP | KM |

48÷52 HP | KM |

||||

|

41÷45 HP | KM |

47÷52 HP | KM |

53÷59 HP | KM |

The table shows the values of the injector nozzle diameter depending on the power output for one cylinder. Nozzle diameter selection values are approximate and suggested. In some cases they must be adjusted to the specific engine and system settings.

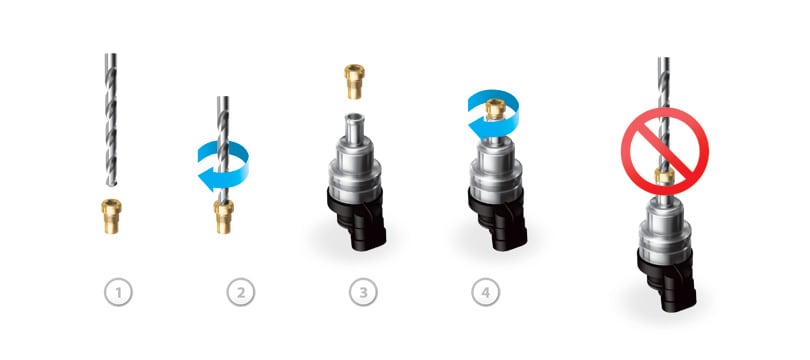

The way of reaming the injector nozzles

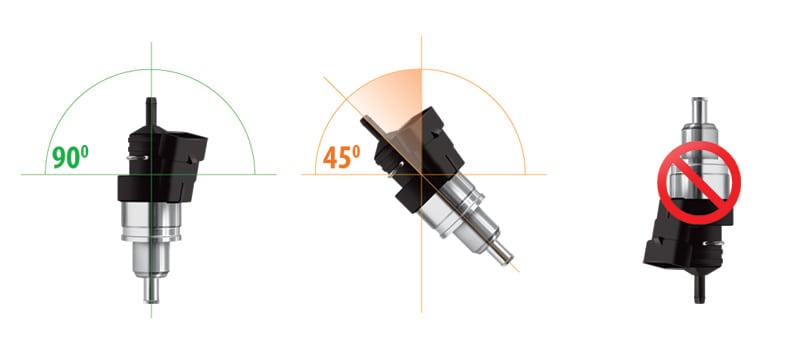

The way of mounting the injectors